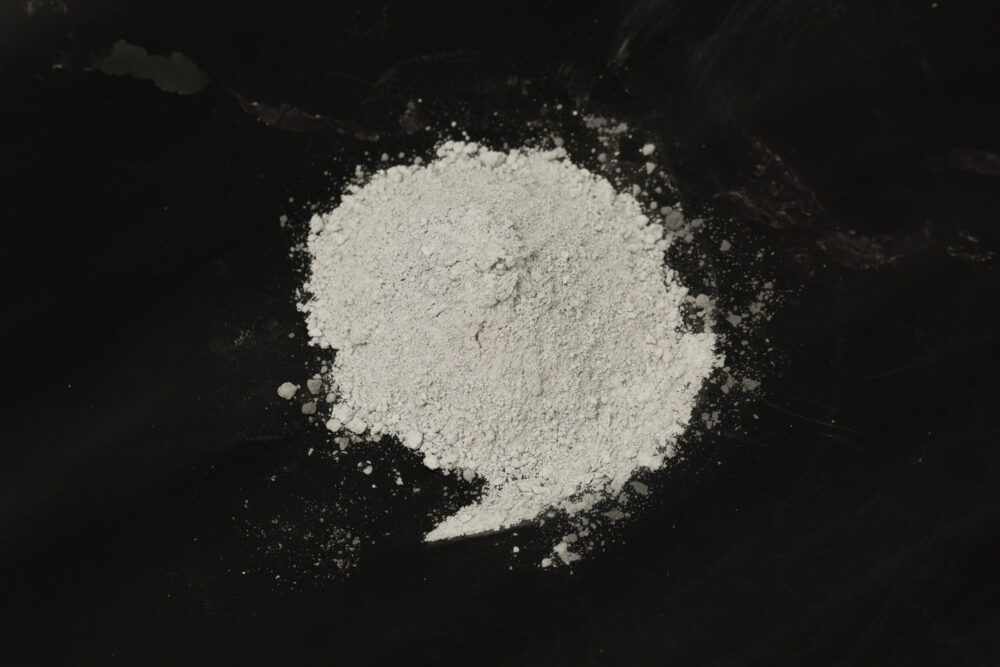

Metallurgical Flux is a chemically engineered product developed to replace Aluminium notches/ bars/shots, Ferro Aluminium & Silico Manganese.

Benefits:

- Eliminates use of Aluminium / Ferro Aluminium

- Reduces Consumption of Silico Manganese

- Improves Manganese recovery

- Reduces metal carryover in Slag

- Controls grain size

The Best Metallurgical Flux Manufacturers in India

Tekor Minerals is the best metallurgical flux supplier in India that has been providing metallurgical flux in India. We offer a quality range of fluxes, which are essential materials to increase productivity in the metallic production industry. We bring you superior quality products and unparalleled service, making Tekor Minerals the best partner for industries that require Metallurgical Flux.

Why Use Tekor Minerals' Metallurgical Flux?

Metallurgical flux is one of the most popular products where Tekor Minerals enjoys a competitive advantage in selling high-quality products. These fluxes are formulated for improving the performance of distinct metallurgical processes as they develop general flux solutions. Here’s why you should choose Tekor Minerals:

High Purity

Tekor Minerals’ metallurgical flux is formulated with a consideration of high purity. Flux products offered by us do not contain any impurities and provide proper results during the process of metal refining and manufacturing.

High Efficiency

The metallurgical flux used has been specifically designed to provide high performances in different metal-making operations. Our flux adjusts the flowability of slag, decreases the melting point, and facilitates the separation of undesired components, meaning the production line is more efficient and requires less time to complete.

Customized Solutions

Tekor Minerals acknowledges fully that every industrial process is different. That is why we offer fully dedicated metallurgical flux options to meet the necessities of a given client.

Key Advantages of Tekor Minerals' Metallurgical Flux

Tekor Minerals’ metallurgical flux has the following benefits that go a long way in enhancing the efficiency, standards, and affordability of your processes.

Enhanced Slag Flowability

The utilization of our metallurgical flux is aimed at the improvement of slag flowability. This enhances the efficiency of getting high purity molten metal from the contaminated one because the impurities are easily separated.

Energy Consumption

Minimizing the melting points and enhancing the characteristics of the slag, our metallurgical flux results in reduced energy consumption during the process. This also leads to cutting down operating expenses while at the same time enhancing energy utilization, making our flux a green solution.

Product Quality Improvement

This is because Tekor Minerals' metallurgical flux enhances the quality of the end product being produced. Our flux contributes to the convenience of washing and improving the purity of metals, which in turn produces high-quality outputs for different sectors.

Applications

Tekor Minerals' metallurgical flux is used in:

Steelmaking

In steelmaking, metallurgical flux is used to purify molten metal and enhance the formation of slag. Our flux can raise the slag fluidity, decrease melting temperature, and improve the quality of the steel.

Aluminum Refining

In aluminum refining, metallurgical flux enables the purging of oxides and other unwanted contamination from the molten aluminum, hence enabling high-quality aluminum output. Tekor Minerals' flux is meant to provide ideal conditions for aluminum refining to take place with no hitches, ensuring the high-quality end product.

Non-Ferrous Metal Refining

The metallurgical flux we supply is also helpful in the purification of nonferrous metals, including copper and lead. The flux helps in cleansing the metal and enhances the rate of refining the metals, thereby helping in removing impurities in the metals.

Choose Tekor Minerals for Your Metallurgical Flux Needs

You can rely on Tekor Minerals to be your metallurgical flux supplier and manufacturer. We provide the best quality flux for your needs.